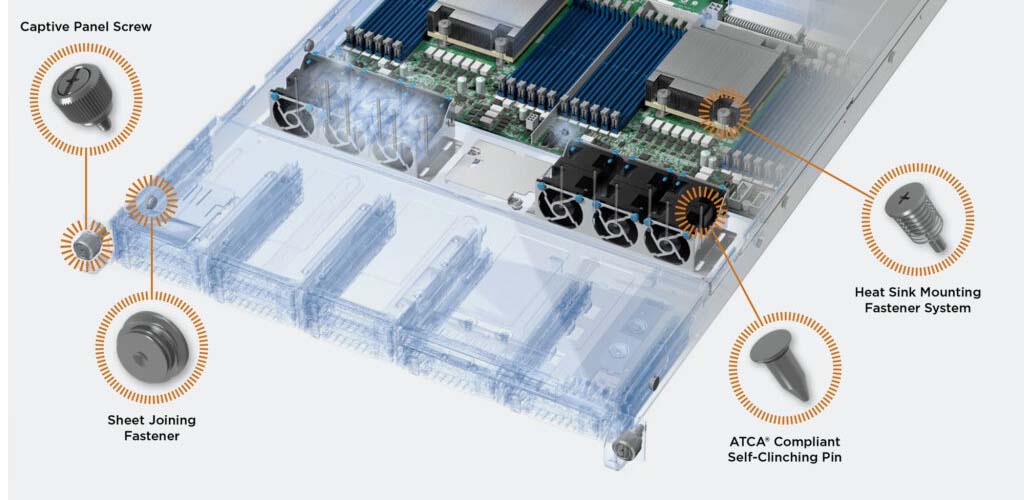

In this fast-paced world of industrial development, making the right choice of self-clinching fasteners is crucial. With numerous options available and evolving techniques, designers face the challenge of staying updated on the latest innovations.

As the catalog of PEM® self-clinching fasteners constantly expands to meet the needs of designers across industries, understanding the basics of self-clinching theory is essential for staying at the forefront of industrial development. In this post, we explore the key factors designers should consider when selecting suitable self-clinching fasteners to ensure high product quality and long lifespan. The steps we will cover include: • Material • Applications • Installation • Product Weight • Aesthetic Considerations

Material

Material Compatibility

Consider the compatibility between the fastener and the materials to be joined, as different materials have varying properties that can affect performance.

Corrosion Resistance

In harsh environments or when joining different materials, corrosion resistance becomes crucial. Choosing a fastener with suitable corrosion-resistant coating or material is essential for longevity and application quality.

Applications

Load

Understanding the load requirements on the joint is crucial for choosing the right self-clinching fastener. Consider factors such as load size, direction, and whether the load is static or dynamic.

Strength Requirements

The strength requirements of the joint directly impact the available options for self-clinching fasteners. Factors like expected load, shear strength, and tensile strength should be carefully considered.

Temperature during Installation and Use

Temperature plays a critical role in the performance and reliability of self-clinching fasteners. Extreme temperatures can affect the mechanical properties of the fastener material, potentially leading to joint failure.

Installation

Accessibility

Consider the practical aspects of installing self-clinching fasteners, ensuring accessibility to both sides of the part for correct installation. Evaluate the simplicity and efficiency of installation to minimize assembly time and costs.

Product Weight

Consider the weight of the product, especially in industries like consumer electronics where lightweight designs are essential. Self-clinching fasteners provide strength and structural integrity while enabling a lightweight design.

Aesthetic Considerations

In certain applications, the appearance of the joint is a significant factor. Consider the "look" of the fastener, its finish, and how well it integrates with the overall design. Choosing self-clinching fasteners that meet aesthetic requirements ensures a visually appealing end product.

Conclusion

In summary, the choice of self-clinching fasteners is a critical aspect of design engineering, where material compatibility, application requirements, installation factors, product weight, and aesthetic considerations play central roles. To ensure success and the long lifespan of products, careful consideration of these factors is essential when selecting the appropriate fastener. If you have any questions or concerns, feel free to contact us at Aero Materiel AB, the distributor for PEM in Sweden and Finland. We are available to provide additional information and support to ensure your self-clinching fastener needs are met in the best possible way. Thank you for choosing us as your partner in self-clinching technology.